Introducing : Advanced Thermal Diffusion Coating

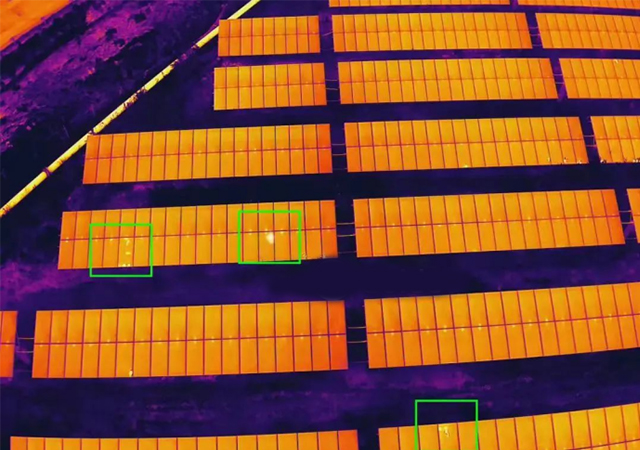

eCoat Solutions presents SolarProtect, a USA-made heat-diffusion nanoceramic coating. Originally designed for the Department of Defense and NASA to protect satellites from thermal extremes, this innovative coating is now available to enhance the efficiency and lifespan of your solar panels, heat sinks, and PCB boards.

Experience unparalleled protection against environmental factors.

Discover the Key Features and Benefits of SolarSink

SolarSink offers a multitude of benefits, including increased processor and component efficiency, reduced electricity costs, and extended panel lifespan. Our nanoceramic coating ensures your solar panels operate at peak performance under a reduced thermal load, even in harsh environmental conditions. Experience the future of solar panel protection with eCoat Solutions.

Key Benefits of SolarSink

Up to 100% increase in heat sink efficiency due to enhanced thermal diffusion over all coated surfaces.

Average reduction in annual electricity usage to run thermal cooling systems, translating to cost savings.

| PROPERTY |

| Color |

| Viscosity |

| Percent Solids (%) |

| V.O.C. Content |

| Odor (liquid) |

| Odor (cured) |

| RoHS |

| REACH |

| Halogens |

| Thermal Stability (cured) |

| Conical Bond (1/8” Mandrel) |

| Cross-Cut Adhesion |

| Coefficient of Friction |

| Specific Gravity |

| Pencil Hardness |

| ASTM TEST |

| D 522-93a |

| D 3359 |

| D 2047 |

| D 891-09 |

| D 3363 |

| RESULT |

| Clear |

| 12 sec. #2 Zahn |

| 20 |

| Exempt per CFR 51.1 / Regulation 8 |

| Slight Solvent |

| None |

| Compliant |

| Compliant |

| None |

| 1200°F / 648.8°C |

| Passed |

| 5B |

| 0.03µ |

| 0.889 |

| 8h |

Application Information

| Estimated Coverage Rate (@ 3 microns) |

| Average Applied Dry Film Thickness |

| Dry to Touch Time (@ 77°F / 25°C) |

| Ambient Cure (Full Properties) |

| 3,500 ft² (325 m²) per gallon |

| 2-10 microns* |

| 20 minutes (average)** |

| 45 minutes | 24 hours for best performance*** |

| *Substrate profile will vary the average coverage rate. **Warm airflow will reduce DTT time. |

| **Exposure to warmer days will help speed the curing process. |